For some time I've wanted to upgrade the instrument panel in the Glastar to a modern EFIS (Electronic Flight Instrument [or Information] System) with a nice, big D.U. (Display Unit) and lots of flight data on it. That technology has been around awhile but has reached a level of affordability only in the last few years. A wag once wrote that if someone wanted to see the airline tech of the future all they had to do was go to Oshkosh and the EAA fly-in to see it in action. Experimenters move the world forward; always have, always will.

The panel when we started. It was very well done for 2002 with all-electric gauges, no vacuum system. That bracket in the middle above the throttle is a mount for a hand-held GPS, a monochrome unit that cost, in 1998, over $1,000! Color displays and GPS come standard on cell phones now, giving truth to the tale that with innovation comes a reduction in cost and much greater value. The GPS incorporated in my new display tells me where I am, where I'm going and where most of the who-elses are flying near me.

My hangar partner, Mark, and Guru Steve planned the new component mounts very well.

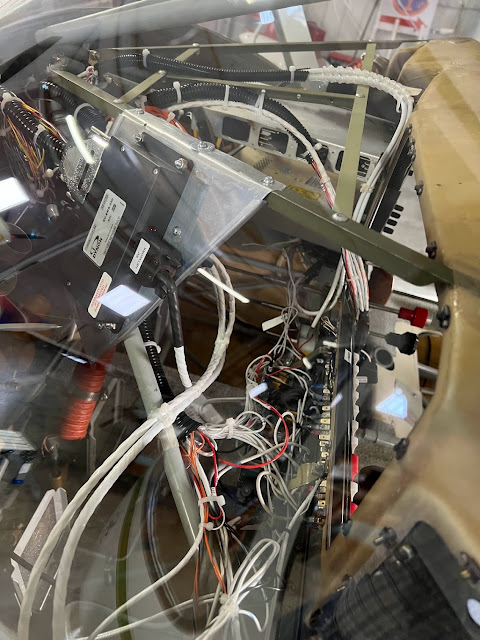

All the space taken up by the old instruments is now open, making room for newfangled network wiring and hub.

The network hub is mounted on the shiny aluminum platform created by Mark and wired up by Steve. Mark put edge protection on and that saved us a lot of cuts and scrapes.

While we had everything opened up I thought it might be time to replace the old wingtip lights and jump into the 21st century with all-LED units. There's no weighty external power supply to eat amps, no bulbs to burn out and the airplane lost about 3 pounds.

The workings of electrons are pretty far outside my realm of knowledge. The beauty of experimental airplanes is the rules give nubs like me a chance to learn as we delve into those mysteries. This being my first foray into electronics and those electronics being essential to my continued health, I recruited Mark and Steve to do the heavy lifting. A project that took them, essentially, 3 weeks would have taken me much, much longer, as in months or a year. I might add that the reason they move so quickly is that Steve and Mark are both airplane builders and both are engineers. They understand this stuff.

The panel after. That 10.4" (diagonal) display has more information on it than the instrument panels on the jets I flew back in the day, and they were hot stuff. I have to calculate a new weight and balance for the airplane but I expect to lose 8-10 pounds with all the new equipment.

There is more to go. The next steps are to install a fuel flow transducer, added to the project after consulting with Steve and Mark and Dynon Avionics. I was thinking old school thoughts (Cubs, Champs, the CallAir Cadet) which said these gadgets won't work with a carbureted engine. My engine has an engine driven fuel pump, so the flow can be calibrated.

Calibrations are a necessity with the new systems, so I'll also be working with Mark, Steve and friends to verify my airspeed readings, measure angle of attack and determine accurate fuel quantities (to be cross-checked with the fuel flow transducer when I take to the air again). The Dynon guy said, half tongue in cheek, that fuel quantity gauges and fuel flow transducers both lie, just in different ways.

All this has been done mostly for the fun of it but also to give me the tools needed to measure the health and efficiency of my engine and the airplane as a whole. After all, I plan to hold onto this one for the duration.

My thanks to Steve and Mark and all the fellows who pitched in to bring this project to fruition. In the process I even learned a thing or two.